30kHz Ultrasonic Cutting for Industrial Applications on Hard and Soft Materials

Description

Basic Info.

| Model NO. | RPS-W30 |

| After-sales Service | 1 Year |

| Voltage | 220V |

| Weight | 6kg |

| Cutting Thickness | 1~7mm |

| Power | 500W |

| Frequency | 40kHz |

| Transport Package | Carton |

| Trademark | RPS-sonic |

| Origin | China |

| HS Code | 8515900090 |

| Production Capacity | 200PCS/Month |

Product Description

30Khz 500W hand held ultrasonic cutting machine

| machine | ultrasonic cutter |

| Frequency(KHz) | 30khz |

| Power | 500w |

| Cutting Blade / Horn | titanium |

| Voltage(V) | 220V |

| Cutting thickness | 1~7mm |

| Horn amplitude | 30μm |

| Equipment weight | 6kg |

Introduction

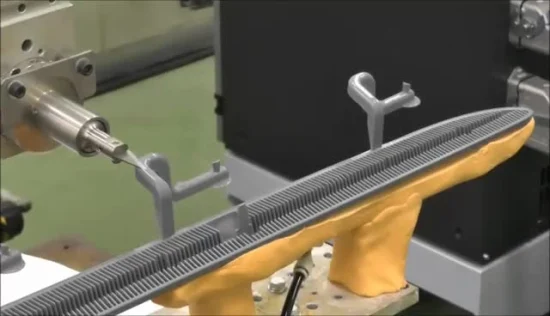

Ultrasonic cutting machine uses ultrasonic energy for cutting processing. There is no need for a traditional cutting edge. Traditional cutting uses a knife with a sharp edge to press the material to be cut. This pressure is concentrated at the cutting edge, and the pressure is very large, exceeding the shear strength of the material being cut, and the molecular binding of the material is pulled apart and cut off. Because the material is pulled apart by strong pressure, the cutting edge of the cutting tool should be very sharp, and the material itself must withstand relatively large pressure. It is not good for cutting soft and elastic materials, and it is more difficult for viscous materials.

Ultrasonic cutting also has a great advantage, that is, it can melt the cutting material while cutting. The cutting area is perfectly sealed to prevent loosening of the tissue of the material being cut (such as flashing of textile materials).So ultrasonic cutting is widly used in fabric, textile, Home textiles ,Non-woven,seat cushion, sound insulation cotton.

Advantages

1. Fast, economical, high sewing strength and strong tensile strength

2. Independent cutting and sewing, with soft melting and trimming effect, no wire loss, no damage, no burrs.

3. No need for auxiliary materials (such as staples, glue, paper clips, etc.). )

4. No time-consuming warm-up and recovery required

5, no pollution, no use of toxic adhesives and solvents, environmental protection and health

6. There is no needle eye on the sewing edge, which can prevent the penetration of chemicals, pathogens and small harmful particles, which is safe and hygienic.

Textile materials suitable for ultrasonic cutting processing: 100% synthetic fibers such as nylon, polyester, polypropylene, certain polyethylenes, modified acrylic resins, certain vinyl compounds, polyurethane compounds, films, Coated paper, etc. It also includes synthetic fibers mixed with 35-50% non-synthetic fiber components.

The ultrasonic heat sealing or cutting process can be used to form continuous work applications, similar to the traditional sewing machine working mode, such as the production of protective clothing, shutters, etc. Welding stand-alone "sewing" equipment or standard ultrasonic welding machines can accomplish this process.

Prev: T

Next: Auto Relay Socket with Line Square Socket Relay Base Supporting Wholesale Customization

Our Contact