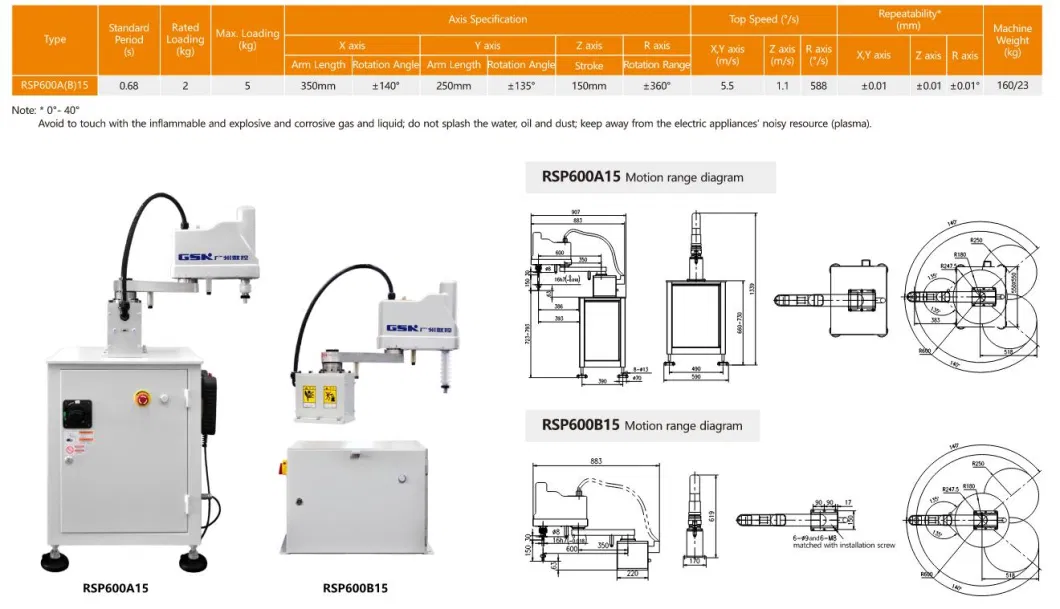

GSK Scara Robot used to perform grasp,assembly,gluing and other operations

Description

Basic Info.

| Model NO. | GSK Scara Robot |

| Axes | 4 |

| Structure | Articulated |

| Reaching | 3150mm |

| Weight | 95kg~110kg |

| Driver | AC Servo |

| Transport Package | Wooden Cases |

| Trademark | GSK |

| Origin | Guangzhou, China |

| HS Code | 8479501000 |

| Production Capacity | 50000 Sets/Years |

Product Description

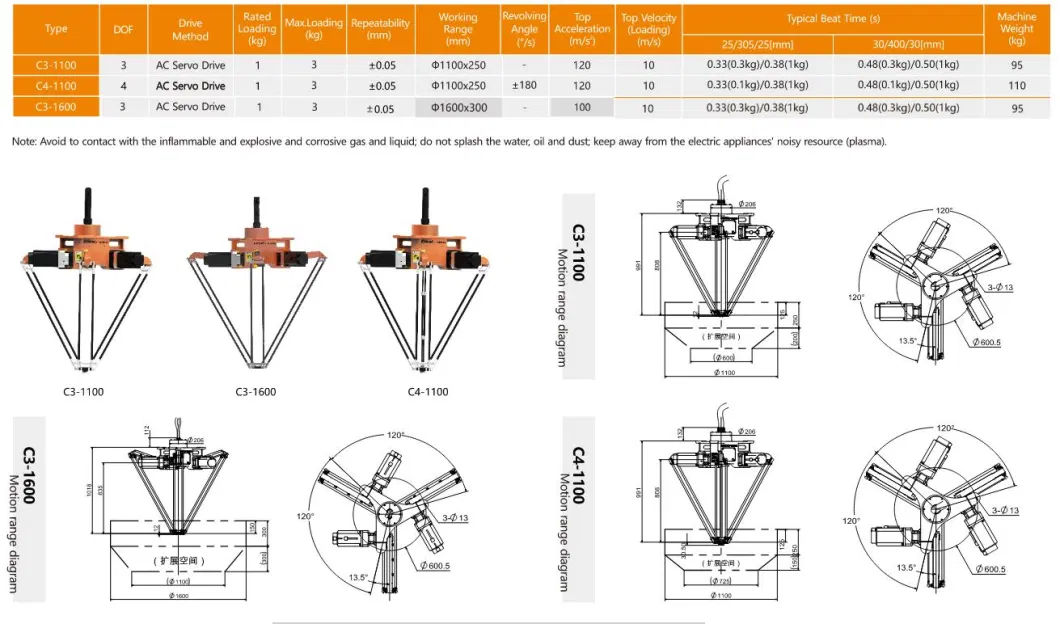

SCARA ROBOT & C series grab robot

Application field: lt is widely used in electron, light industry, food and medicine etc., which canachieve the high-speed holding/unholding and sorting packing operations.Product Parameters

Key Functional Components

Mainly include: controller (electric cabinet & teaching pendant)SJTR Series Servo Motor, GE Series AC Synchronic Servo Drive UnitHypocycloid Cross Roller Reducer.Controller (Cabinet&Teaching Pendant)

GSK Production Line Unit Control System

&.It is for a machining field's monitor management system to assemble lines of production equipments used for machining all kinds of parts;

&.Utilizing GSK-LINK on-site bus realizes high-speed connection between the CNC machine, industrial robot and production line's auxiliary operation device:

&.On-line and off-line programming support;

&.Simply humanized operation;

&.Maximally improve production efficiency and stability of production quality Reduce labor cost:

&.Optimize and improve customers' management system.GSK General Control Management System

| &.It is used for achieving the"Digitalized factory","Intelligent workshop" management system; |

| &.CAM and CAPP application and management; |

| &.Conveniently flow plan fast; |

| &.Count and regulate production capacity; |

| &.Equipment utilization statistics; |

| &.Production flow interference; |

| &.Elevate C/T and so on. |

Applications

1.GSK RMD200 robot applies the rice bag palletizing for one company

Customer Requirements

1.Connecting with manual package and package-sealing production line; replacing the manual to performthe automatic palletizing;

2.Compatible 5-50kg, total five specifications for the rice bag.

Application Effect

1.Connecting with the artificial production line, achieving the rice bag automation technology process: putdown, guide, height adjustment, flat and palletizing capture;

2.It is used the product-change adjustment by labor force, and the production-change can be reduced byMPG and rocker to improve the working efficiency and compatible five specification for the rice bag.

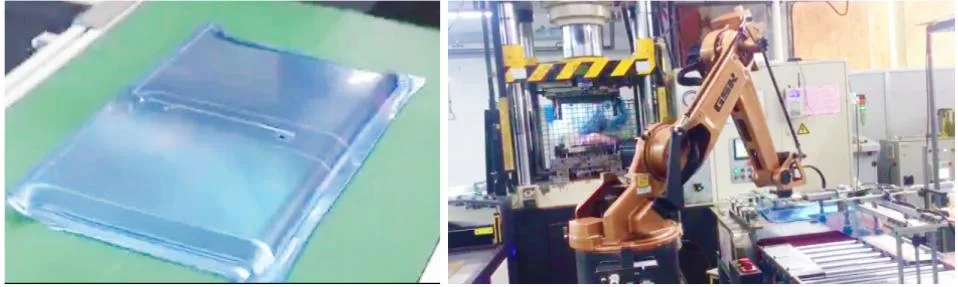

2.GSK RMD20 robot applies the automatic production loading/unloadingfor kettle decorative boardCustomer Requirements

1.That the robot replaces the labor force to complete the workpiece oil-brushing, loading/unloading for theoil press, and the production process of laser cutter's loading/unloading as well;2.Production types are variable, and single batch production is less; wide universality of robot's fixture sothat it needs to capture the loading/unloading for products with different appearance;3.The machining time of laser cutter is 20 seconds; production capacity: 180pcs/hour.Application Effect1.It is used the compatible and flexible manipulator design and settled multiple types by less cost as wellthe troubles when the pilot production shares with a same production line;2.The production character of the appliance industry is variable types, strong equipment compatibility,frequent and single of production process, intensive labor force and short production period; if it usesthe robot to replace the labor, it will reduce the production cost and guarantee the production cycle

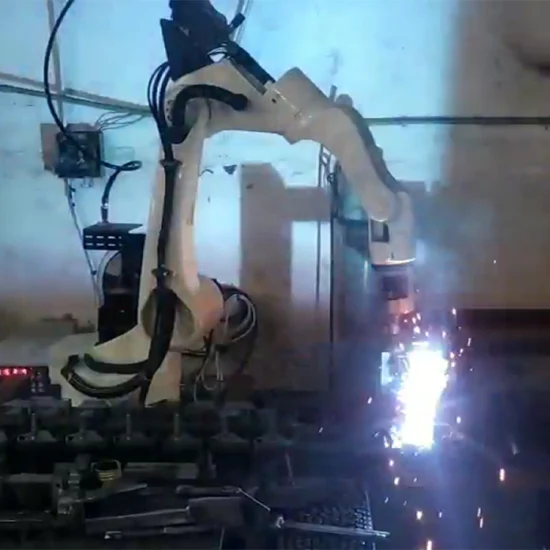

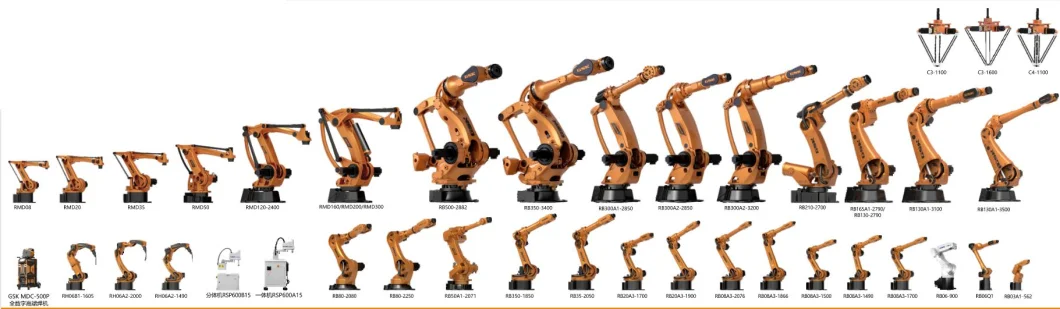

Robot FamilyWith the industry control technology R&D, and manufacture experience for more than 30 years, GSK has produced our industrial robots with independent intellectual property rights, including robot controllers,servo motors and servo drivers and other key functional components. Presently, GSK's industrial robots are divided into 6 series covering transportation, welding, polishing, painting, stacking and paralleling, up to 30 kinds of product.

Being one of enterprises undertaking"National ntelligent Manufacturing Equipment DevelopmentSpecial Project", GSK independently researches and develops industrial robots carrying high quality andhigh technology of GSK's CNC systems. According to users' requirements, it provides robots with superiorperformance, designs and manufactuers fixture and conveyor required for automation solution.

Main products:

GSK CNC System Idustrial robot

Full electric injection molding machine CNC machine

our partners

Prev: Biobase Spray Disinfecting Atomizing Disinfection Robot

Next: Hot China Detek Insulating Glass Production Secondary Sealing Robot 2500

Our Contact