Head and Tail Rotary Turning Table L Welding Positioner Lifting Elevating Turntable

Overview Package Size 300.00cm * 300.00cm * 200.00cm Package Gross Weight 1000.000kg A. Usage and Application: 1. Weldin

Description

Basic Info.

| Model NO. | HB1 ~ HB500 |

| Max Eccentricity Distance | Custom Made |

| Tilting Angle | 0-120° |

| Voltage | Based on Customer Demand |

| Welding Turning Rolls Type | Adjustable |

| Welding Tilter Type | Flexible Combination |

| Condition | New |

| Revolving Drive | Motor/ Servo Drive |

| Welding Turntable | Single/ Double Welding Turning Table |

| Rotation Angle | 0 ~ 360° |

| Tilt Angle | 0 ~ 120° |

| Degree of Freedom | 3: Rotation, tilt, and lift |

| Rotating Speed | Inverter Control |

| Workpiece Clamp | Welding Fixture, Clamp |

| Workpiece Elevating Control | Hydraulic Drive, Reliable and Safe |

| Control Axis | Single/ Double/ Three Axis |

| Transport Package | Integral Package |

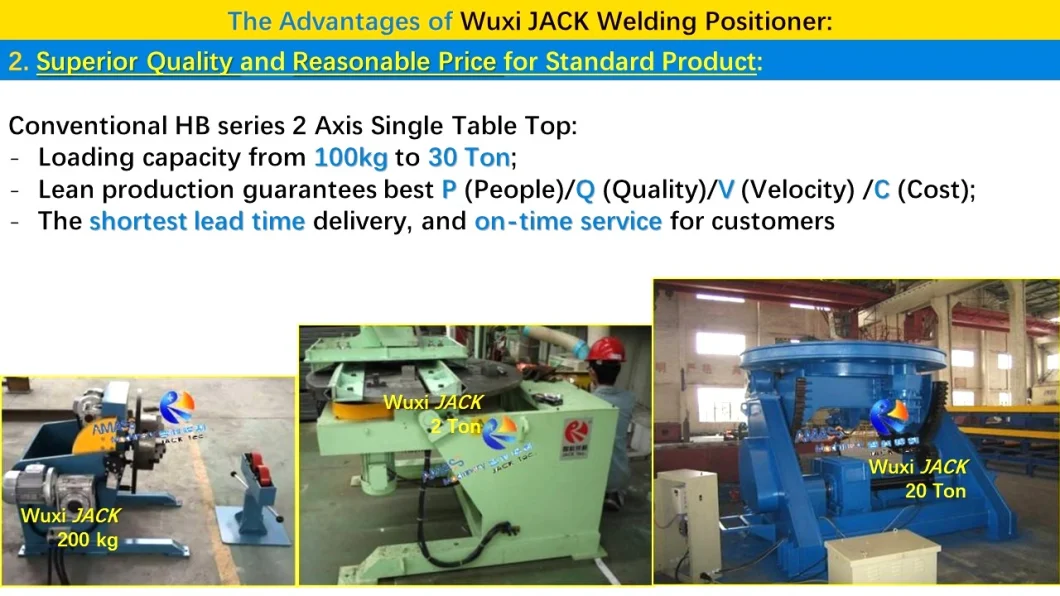

| Specification | Loading Capacity from 100kg to 30Ton |

| Trademark | Wuxi JACK and AMASS |

| Origin | Wuxi, China |

Packaging & Delivery

Package Size 300.00cm * 300.00cm * 200.00cm Package Gross Weight 1000.000kgProduct Description

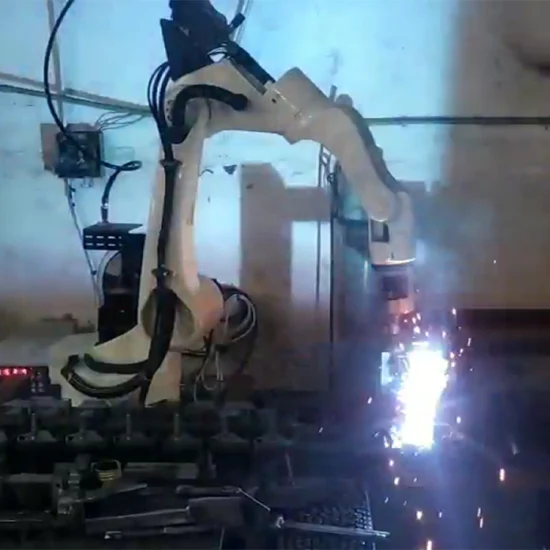

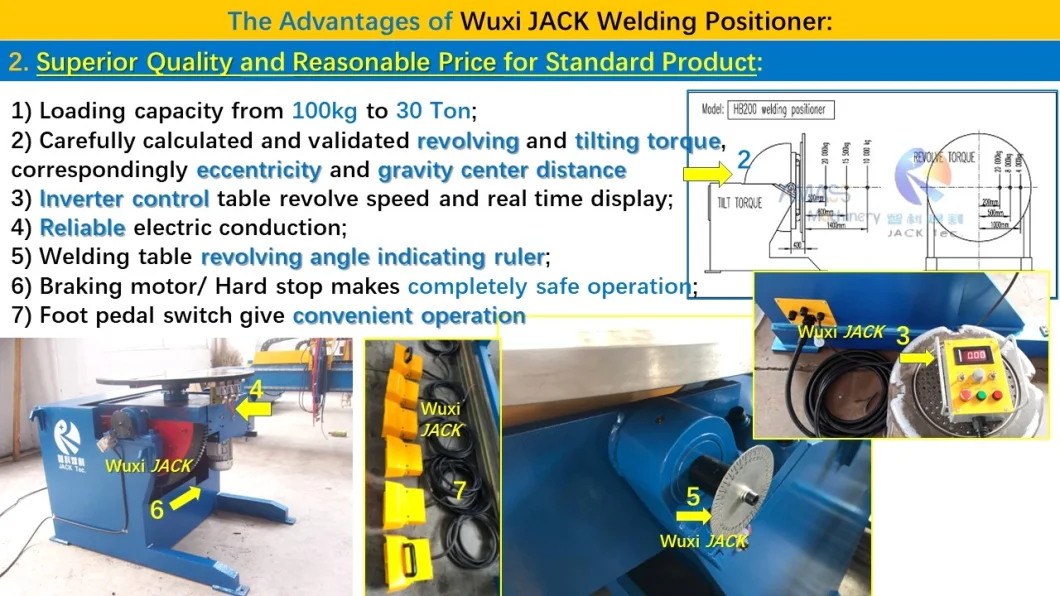

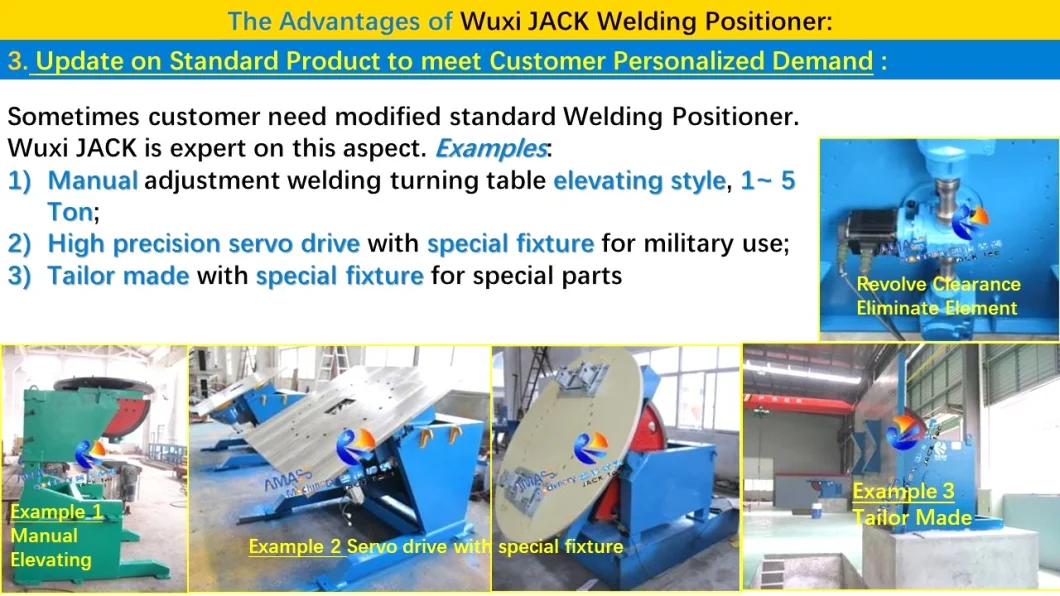

A. Usage and Application: 1. Welding Positioner is for changing workpiece position:1) 0° ~ 360° infinite rotation;2) 0° ~ 120° tilting;3) Elevation;4) Moving;To get optimum welding position for ideal ergonomics, and best quality;2. Welding Center: With other Welding Equipment such as Welding Rotator/ Welding Column and Boom, Welding Positioner can be composed into Welding Center, fulfilling complicated tasks.B. Advantages of (Wuxi JACK) Wuxi AMASS Welding Positioner:Welding Positioner is superior product of Wuxi JACK (Wuxi AMASS). Below slides give graphical introduction on our strong points:

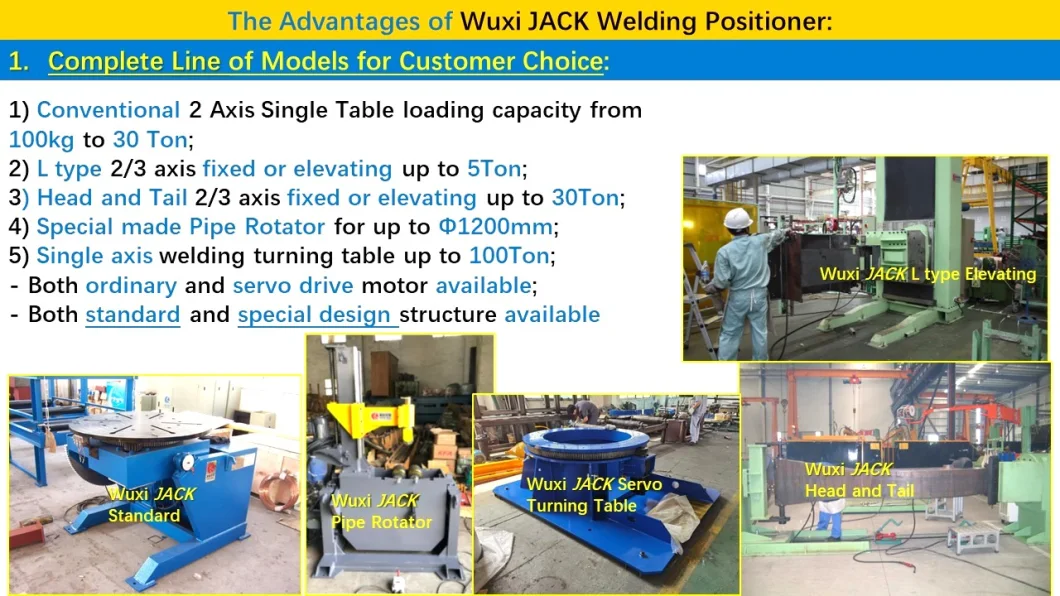

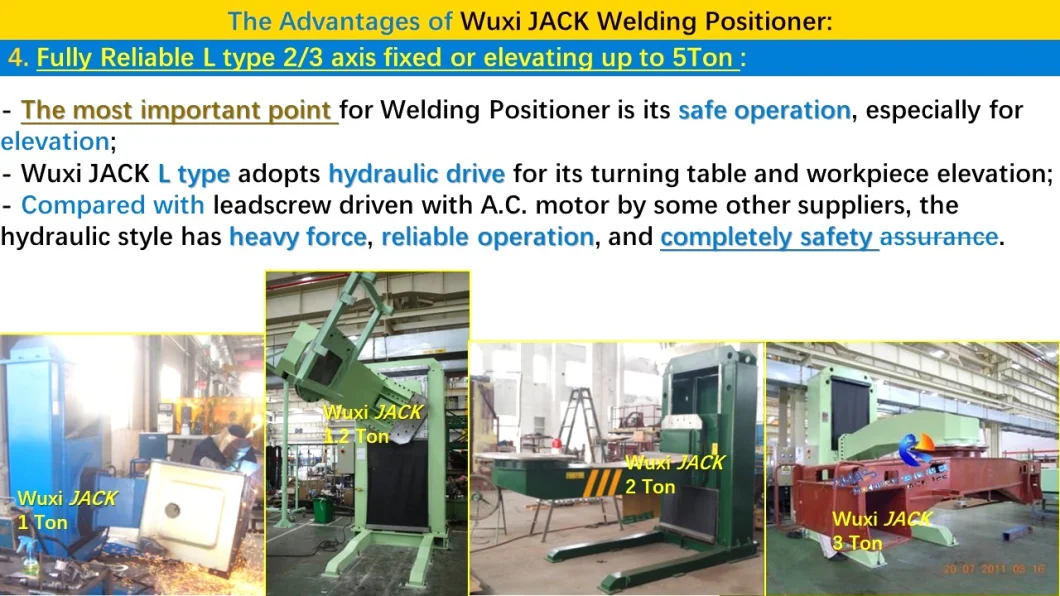

C. Classification: Wuxi JACK (Wuxi AMASS) Welding Positioner comes into 6 categories:1. HB series Two Axis Welding Positioner: (Fig.1)1) Two Axis: 0° ~ 360° infinite rotation, 0° ~ 120° tilting;2) Loading capacity from 100kg to 30 Ton;3) Optional variations:a) Work table elevating: (Fig.2)b) Servo drive;c) Special rotary table with special welding fixture;d) 2 sets of separate rotary table for workpiece joint through; (Fig.3) 2. LBS series Two/ Three Axis L type Welding Positioner: (Fig.4)

| LBS10 Elevating and Revolving L type Welding Positioner | |

| Max. Loading Capacity of Welding Turning Table | 1000kg ~ 4000 kg |

| Up and Down Stroke of L arm | 800 mm ~ 2000 mm |

| Welding Turning Table Size | Φ460 mm ~ Φ1200 mm |

| L Arm Revolving Velocity in Vertical Plane | 1.3 ~ 2 rpm |

| Welding Turning Table Rotation Speed | 0.2 ~ 2 rpm, controlled with inverter |

| Power of L Arm Vertical Revolving Hydraulic Motor | 1.1 kW ~ 4 kW |

| Power of Welding Turning Table Rotation Motor | 0.75 kW ~ 4 kW |

1) Two Axis: 0° ~ 360° infinite rotation, 0° ~ 360° tilting in the air;2) Loading capacity up to 4 Ton;3) Rotary welding table elevation;

3. HTHB series Two/ Three Axis Head and Tail Welding Positioner: (Fig.5)1) Two Axis: Elevation; 0° ~ 360° tilting in the air;2) Optional the 3rd axis: 0° ~ 360° infinite rotation;3) Two types of Mechanical Structures: a) Both columns fixed; b) One column fixed, the other column moving;4) Loading capacity up to 20 Ton;4. SAHT Series Single Axis Horizontal Welding Turning Table: (Fig.6)1) Loading capacity up to 30 Ton;2) Servo drive loading capacity up to 3 Ton;5. SHB Series Single Axis Vertical Welding Positioner: (Fig.7)Loading capacity up to 5 Ton;6. PR Series Pipe Rotator Welding Positioner: (Fig.8)1) This is for welding Pipe Flange Assembly / Pipe Elbow Assembly;2) Two Axis: 0° ~ 360° infinite rotation; -45° ~ 45° tilting.

Our AdvantagesAfter Sales ServiceFAQ1. Q: What is the relationship between Wuxi AMASS and Wuxi JACK?

A: Wuxi AMASS and Wuxi JACK are the same company: Wuxi AMASS is wholly owned subsidiary of Wuxi JACK, for overseas trading Wuxi JACK products;

2. Q: What is the nature of your company?

A: Business scope of Wuxi JACK and AMASS covers design, production and selling;

3. Q: What is the range of your company product?

A: Wuxi JACK and AMASS is a professional supplier in Welding and Cutting Industry;Main products of our company include:1) Steel structure production equipment (H Beam/ BOX Beam/ T Beam);2) Edge Milling Machine;3) Structure member Beam end face milling machine;4) CNC Plate Cutting Machine;5) CNC Pipe Cutting Machine;6) Various kinds of conventional and special design welding equipment and machine;7) Various kinds of conventional and special design Straightening machine, etc.;

4. Q: What is the strength of your company?

A:1) Wuxi JACK was founded by 3 senior engineers 15 years ago;2) Engineering team of our company has over 20 years experience on Welding and Cutting industry;3) Operation manager has 14 years experience working in an American Fortune Global 500 Dow Jones Industrial Index Company as senior Project Manager;4) The competitive edge of our company is special design products based on customer demand.

5. Q: What are service terms of your company?

A:1) During business negation: a) Make technical proposal and quotation;b) Answering customer questions;c) Make final contract and technical agreement;2) During order to delivery value chain:a) Design, validate, and manufacture products for customers;b) Inform progress of manufacture to customers;c) Arrangement for package and shipment of products to customers;3) After sale service: a) Technical support on installation and commissioning at customer site;b) 1 year guarantee from the date of acceptance;c) Feedback any technical issues within 4 hours upon getting the notice;

6. Q: Where is location of your company?

A: Wuxi city, Jiangsu province, 130km from Shanghai

Our Contact

Send now